In recent years, with research on agricultural technology, it has been discovered that glyphosate is a non-selective, non-residual herbicide that is very effective against perennial root weeds. It is widely used in rubber, mulberry, tea, orchards and sugarcane fields. . What is the ZHJK series patented graphite esterification reactor that affects the production efficiency of the herbicide glyphosate? This article gives you a brief introduction.

ZHJK model patented graphite esterification reactor is a kind of graphite heat exchanger equipment specially designed for the esterification reaction section encountered in the production process of glyphosate. In the scope of application required by actual working conditions, graphite heat exchangers are used in a wide range of applications. According to product classification, they can be divided into round-hole graphite heat exchangers, tubular graphite heat exchangers, and rectangular block-hole graphite heat exchangers. Heater, bidirectional anticorrosive graphite heat exchanger, graphite esterification reactor, graphite phosphoric acid concentration heater, smelting special graphite heater, graphite evaporator, it can be seen that the ZHJK model patented graphite esterification reactor is a graphite heat exchanger One kind, and the application range of graphite heat exchanger is much wider.

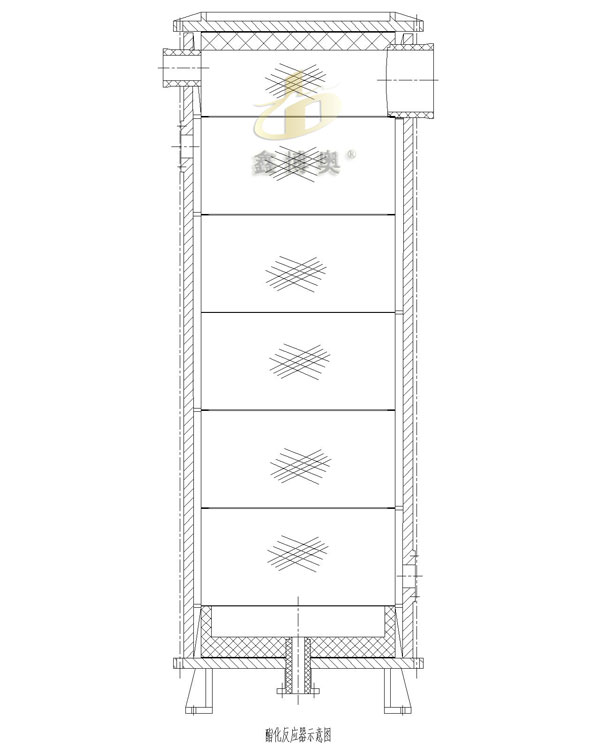

According to the structure design drawing of the ZHJK model graphite esterification reactor, the material inlet outside the equipment is installed on the graphite reactor. The purpose of this design is to better promote the entry of materials and then exchange heat with cooling water to accelerate the graphite ester. The heat exchange efficiency of the chemical reactor increases the production output of the herbicide glyphosate.

Secondly, in order to ensure that the equipment has good corrosion resistance, corrosion-resistant impregnated graphite is applied to the equipment, and because the graphite itself has the physical characteristics of efficient heat conduction, the heat exchange efficiency of the reaction is improved, and the occurrence of side reactions is reduced. Probability. At this point, everyone can roughly understand what a graphite esterification reactor is. As far as the graphite heat exchanger manufacturer is concerned, its application section is a technical renovation project. For the price and detailed design parameters of the graphite esterification reactor (applicable to different temperatures, different pressures, different media, and different working conditions), please contact Contact the technical staff to get a free one-to-one customized design plan. The above is original by Xinboao graphite heat exchanger equipment manufacturer, please indicate the source for reprintingwww.xinboao.cn