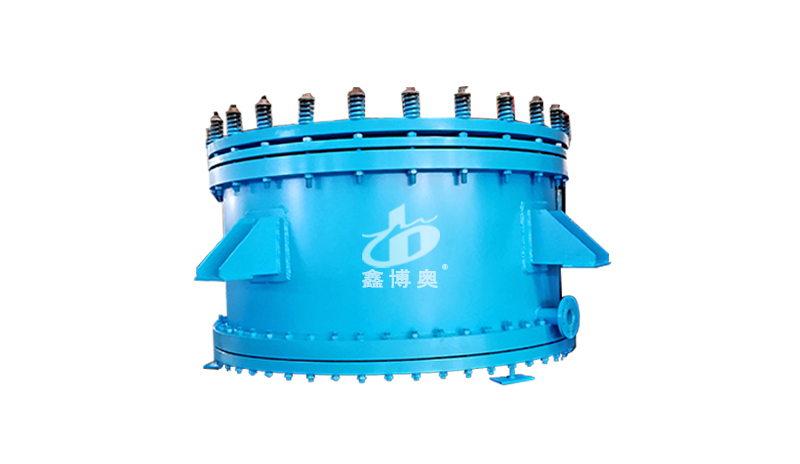

The graphite evaporator is composed of a graphite gas cavity,

Service Hotline :

+8618613619129

The graphite evaporator is composed of a graphite gas cavity, a graphite upper and lower head, a graphite heat exchange block, a carbon steel shell, and a pressure spring. The graphite heat exchange block is drilled with horizontal and vertical holes. The two are not connected, and the vertical holes are corrosive. Material, steam through the horizontal holes, using a pressure spring as an automatic compensation device for thermal expansion and contraction.

Graphite heat exchangers can be used in other mechanical equipment related to heat energy exchange. Frosting can occur at zero degrees, and the zero-degree operating condition is beneficial to the heat exchange of the unit. When the surface of the graphite evaporator starts to have micro-frost, it will affect the heat exchange. The effect of the device is improved. It can strengthen the exhaust, but with the thickening of the frost layer, the resistance of air circulation increases, which will inevitably hinder air circulation. The evaporator absorbs heat through air, and the air flow decreases, so the heat absorption also decreases. At this time, the unit Performance began to diminish. These are all related to the design issues of the evaporator, such as the evaporator fin spacing, evaporation area, evaporator thickness, and tube connection have a direct impact.